European

Southern

Observatory

The prefocal station, or PFS, is the link between the telescope and its instruments.

In addition to distributing light to the science instruments, it helps control the alignment of the mirrors and plays an important role in allowing the ELT to obtain extremely sharp images.

In addition to distributing light to the science instruments, it helps control the alignment of the mirrors and plays an important role in allowing the ELT to obtain extremely sharp images.

The prefocal station, or PFS, is the link between the telescope and its instruments.

In addition to distributing light to the science instruments, it helps control the alignment of the mirrors and plays an important role in allowing the ELT to obtain extremely sharp images.

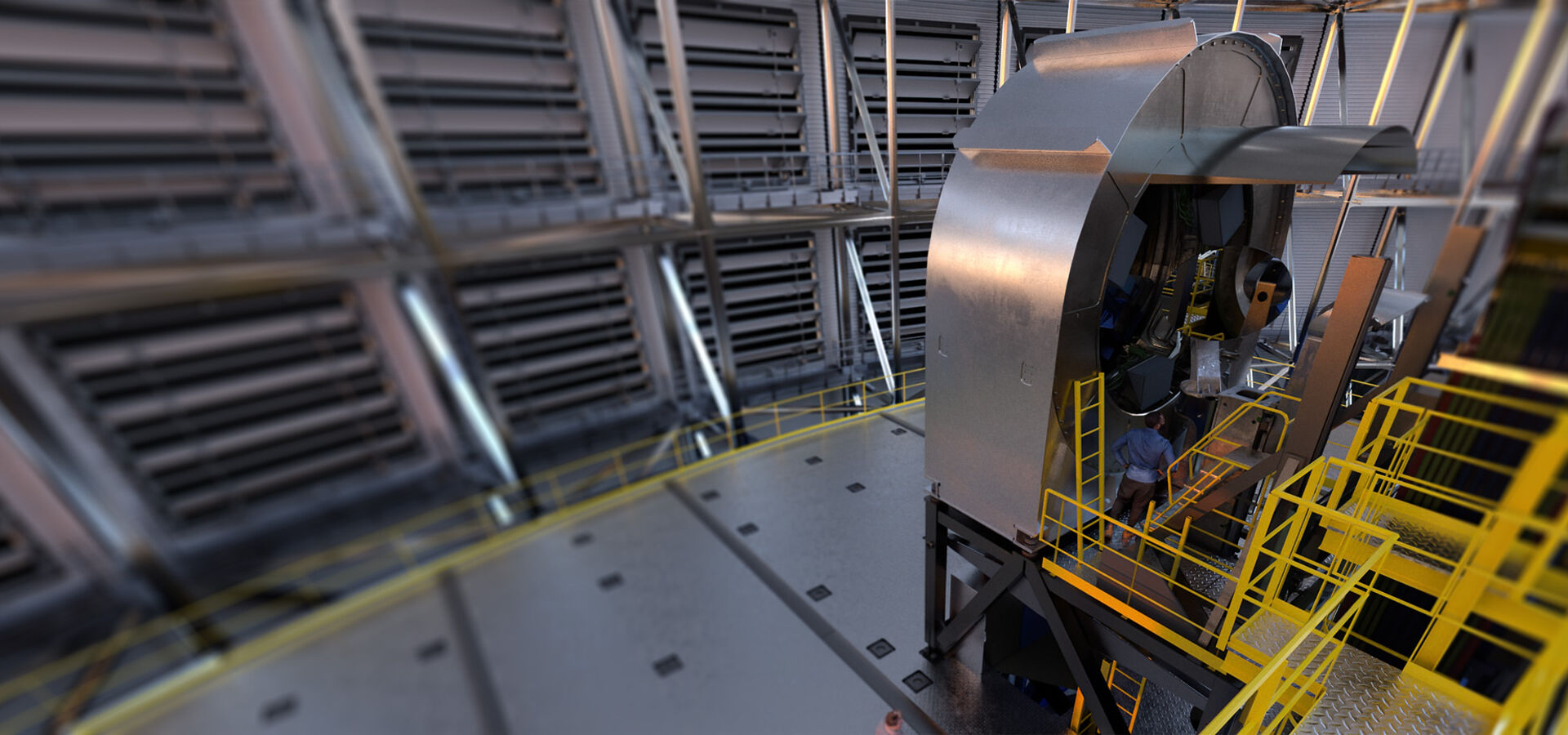

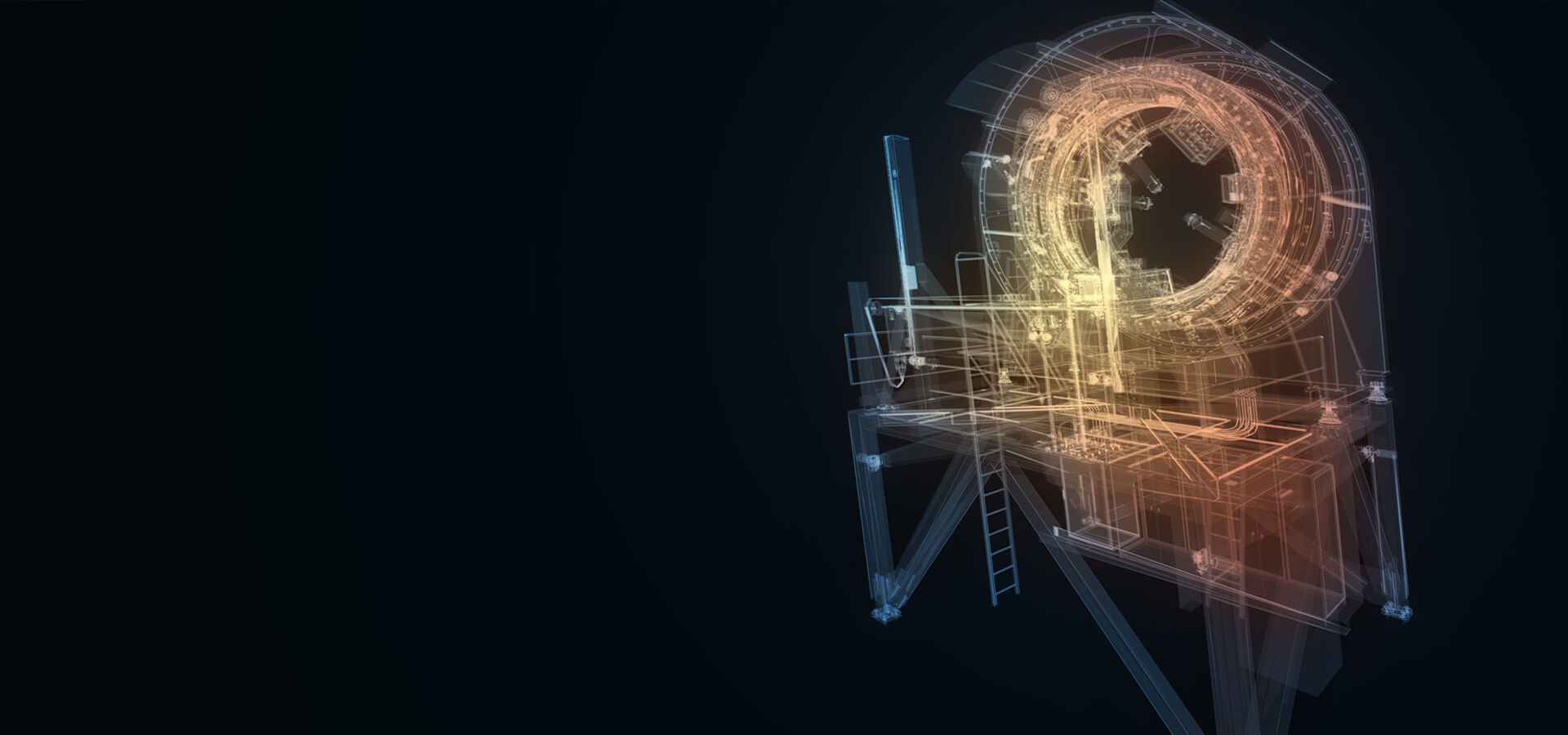

To study the Universe in detail and produce the sharpest images possible, the ELT requires not only sophisticated mirrors and advanced science instruments, but also a tight link between these two components. This link takes the form of two massive structures, the prefocal stations (PFS-A and PFS-B), which stand over 12 metres high and sit on the platforms, called Nasmyth platforms, on either side of the ELT’s giant tube structure. The name comes from the fact that the prefocal stations are the last component in the telescope’s light path, right before the light comes to a focus.

One of the most important functions of a prefocal station is to distribute light to the appropriate science instrument, which will then capture and analyse it. The instruments themselves are also on the two Nasmyth platforms, and the light is distributed to them via flat mirrors on the prefocal stations.

Another main function of the PFS is sensing star light to control the telescope mirror alignment when observing. The PFS observes stars close to the target, known as guide stars, to check that the ELT’s mirrors are aligned and that the telescope is correctly pointing at the target.

The PFS also hosts a phasing and diagnostic station (PDS), which is equipped with special sensors used for testing the telescope before and during operation. As the name indicates, the PDS is used for general diagnostics, and to ensure that the giant primary mirror of the ELT (composed of 798 segments) maintains an ideal shape and acts as one giant mirror — a process called phasing.

The ELT will host up to three or four science instruments on each Nasmyth platform. This is quite different to ESO’s Very Large Telescope (VLT): each of its Unit Telescopes serve a single science instrument at each Nasmyth focus. In the case of the VLT, the telescope provides a rigid attachment point for a single science instrument that is tightly coupled to the telescope’s mechanical rotation axis and the optical axis. In contrast, the ELT instruments are free-standing structures on the Nasmyth platform or in the Coudé laboratory. The telescope beam is directed in turn to whichever instrument is currently making a science observation.

One of the functions of the PFS is to distribute the light for science observations using flat mirrors that can be moved into position to send the light from the telescope to the science instruments. When they are deployed, these mirrors are the sixth mirror (M6) in the telescope’s optical path. The PFS can use one of two mirrors: one for the Nasmyth instruments (at lateral focus, known as M6N) and another for the Coudé instruments (known as M6C). These M6 mirrors can also be fully retracted from the telescope’s optical beam so that the instrument at the centre of the Nasmyth platform (the straight-through instrument) receives the telescope’s light.

The M6N mirror has an optically flat elliptical shape and is extremely flat: to within a few tens of nanometres. Its optical surface has dimensions of 1440 mm x 1042 mm and it has a highly reflective metal coating. The M6C mirror is slightly smaller with an optical aperture of 691 mm x 500 mm along the major and minor axes respectively.

Drifting out of alignment

During science observations, the ELT measures images of stars close to the science target in addition to the science object itself. These additional stars are known as guide stars. The guide-star images are analysed by the telescope control system to obtain information about the alignment of the telescope, which in turn is used to actively position and control the mirrors and telescope main structure to keep the telescope well aligned.

There are several effects that might cause the ELT to slowly drift out of optimum alignment during science observations. Slight changes in temperature inside the telescope chamber cause the metal structure and optics to thermally expand, which changes its dimensions and causes the mirrors to move out of alignment. The direction that gravity acts on the mirrors and their supporting structures also varies as the telescope is tilted up and down to follow the motion of stars in the sky. This causes deflections in the telescope structure and in turn errors in its optical alignment. These effects, which typically range in magnitude from hundreds of micrometres to a few millimetres, seem small on the scale of the ELT telescope. However, the optical alignment of the telescope is very sensitive to misalignments of this size, so the mirror positions and shapes are actively controlled to minimise the optical errors that build up during the science exposure: a process called active optics.

The Natural Guide System

The PFS Natural Guide System includes an adapter subsystem, which has the task of observing and measuring up to three guide stars simultaneously with the science observation. It does this with the help of its three sensor arms mounted on circular bearings. The sensor arms are motorised so that they can move on a circular path around the bearing and radially towards the centre of the adapter. In this way, the sensor arms can find guide stars in the telescope optical beam and follow them as the sky appears to rotate during a science observation.

To observe a guide star, each sensor arm includes a flat pick-off mirror at its tip that reflects a small part of the telescope’s light into the sensor arm. Inside the sensor arm, the optical beam is split into two channels using a wavelength splitter known as a dichroic mirror.

The longer wavelength channel, covering 800–950 nm, is sent to an imaging camera that makes an image of a guide star. This tip-tilt camera measures the position of the star and generates a signal that can be used to control the pointing direction of the telescope.

The short wavelength channel, covering the wavelength range 500–800 nm, is sent to a wavefront sensing camera. This camera determines how much the starlight is distorted by both changes in mirror alignment and turbulence in the atmosphere. It does this by measuring aberrations in the telescope’s optical beam, for example the focus error and astigmatism. The wavefront sensing camera also has the capability to measure higher order aberrations, up to around 400 spatial modes at a frame rate of up to 500Hz or more. Aberrations can be corrected using a deformable mirror, like the ELT’s M4, a process known as adaptive optics.

Each sensor arm is approximately 1200mm long and has a mass of around 300kg. The required positioning accuracy of each sensor arm is a few hundred micrometres under all operating environmental conditions and for motion speeds up to approximately 5–10 mm/second.

In addition to supporting science observation directly, the PFS is also required to perform several tasks related to commissioning and maintenance of the telescope. The most important of these are keeping the telescope primary mirror phased, diagnosing problems, and helping to maintain the telescope’s active and adaptive functions.

The ELT primary mirror, with its 798 individual segments, acts as a single continuous optical surface when the telescope is observing. When the shape of this surface is ideal we say that the mirror is well-phased. The wavelength of light captured by the ELT ranges from a few hundred nanometres to 24 micrometres. To produce near perfect (diffraction-limited) images, the positions of the segments relative to each other must be controlled to tens of nanometres. Motors known as position actuators control the position of the segments to maintain their relative positions using signals from edge sensors attached to each segment. However, over time these sensors will drift slightly, which can be caused by natural variations in temperature, humidity and the inherent drift of the measuring electronics. This drift of the edge sensors will cause M1 to lose its ideal shape over a projected time scale of around two weeks.

The PDS subsystem of the PFS will periodically measure the shape of M1 using guide star measurements and allow the position errors of the segments to be calculated and corrected by updating the segment control positions. This phasing measurement can be performed by using a wavefront sensor to analyse the characteristic diffraction patterns produced by unwanted steps between segments that are not well-phased. The PDS is installed in the PFS structure on the lower level and receives the telescope light reflected downwards by the M6C mirror.

The PDS also contains several other optical sensing modules that will help test the telescope when it is first constructed and later enable troubleshooting and maintenance of the ELT over its operational lifetime.

We use cookies that are essential for accessing our websites and using our services. We also use cookies to analyse, measure and improve our websites’ performance, to enable content sharing via social media and to display media content hosted on third-party platforms.

The European Organisation for Astronomical Research in the Southern Hemisphere (ESO) is the pre-eminent intergovernmental science and technology organisation in astronomy. It carries out an ambitious programme focused on the design, construction and operation of powerful ground-based observing facilities for astronomy.

This Cookies Policy is intended to provide clarity by outlining the cookies used on the ESO public websites, their functions, the options you have for controlling them, and the ways you can contact us for additional details.

Cookies are small pieces of data stored on your device by websites you visit. They serve various purposes, such as remembering login credentials and preferences and enhance your browsing experience.

Essential cookies (always active): These cookies are strictly necessary for the proper functioning of our website. Without these cookies, the website cannot operate correctly, and certain services, such as logging in or accessing secure areas, may not be available; because they are essential for the website’s operation, they cannot be disabled.

Functional Cookies: These cookies enhance your browsing experience by enabling additional features and personalization, such as remembering your preferences and settings. While not strictly necessary for the website to function, they improve usability and convenience; these cookies are only placed if you provide your consent.

Analytics cookies: These cookies collect information about how visitors interact with our website, such as which pages are visited most often and how users navigate the site. This data helps us improve website performance, optimize content, and enhance the user experience; these cookies are only placed if you provide your consent. We use the following analytics cookies.

Matomo Cookies:

This website uses Matomo (formerly Piwik), an open source software which enables the statistical analysis of website visits. Matomo uses cookies (text files) which are saved on your computer and which allow us to analyze how you use our website. The website user information generated by the cookies will only be saved on the servers of our IT Department. We use this information to analyze www.eso.org visits and to prepare reports on website activities. These data will not be disclosed to third parties.

On behalf of ESO, Matomo will use this information for the purpose of evaluating your use of the website, compiling reports on website activity and providing other services relating to website activity and internet usage.

Matomo cookies settings:

Additional Third-party cookies on ESO websites: some of our pages display content from external providers, e.g. YouTube.

Such third-party services are outside of ESO control and may, at any time, change their terms of service, use of cookies, etc.

YouTube: Some videos on the ESO website are embedded from ESO’s official YouTube channel. We have enabled YouTube’s privacy-enhanced mode, meaning that no cookies are set unless the user actively clicks on the video to play it. Additionally, in this mode, YouTube does not store any personally identifiable cookie data for embedded video playbacks. For more details, please refer to YouTube’s embedding videos information page.

Cookies can also be classified based on the following elements.

Regarding the domain, there are:

As for their duration, cookies can be:

Cookie settings: You can modify your cookie choices for the ESO webpages at any time by clicking on the link Cookie settings at the bottom of any page.

In your browser: If you wish to delete cookies or instruct your browser to delete or block cookies by default, please visit the help pages of your browser:

Please be aware that if you delete or decline cookies, certain functionalities of our website may be not be available and your browsing experience may be affected.

You can set most browsers to prevent any cookies being placed on your device, but you may then have to manually adjust some preferences every time you visit a site/page. And some services and functionalities may not work properly at all (e.g. profile logging-in, shop check out).

The ESO Cookies Policy may be subject to future updates, which will be made available on this page.

For any queries related to cookies, please contact: pdprATesoDOTorg.

As ESO public webpages are managed by our Department of Communication, your questions will be dealt with the support of the said Department.